This sample Adopting RFID Research Paper is published for educational and informational purposes only. Free research papers are not written by our writers, they are contributed by users, so we are not responsible for the content of this free sample paper. If you want to buy a high quality research paper on any topic at affordable price please use custom research paper writing services.

In most of today’s modern companies, information technology (IT) forms the backbone on which information is circulated throughout and beyond the organization to inform employees, customers, trading partners, and other entities about the activities of the organization. For example, internal IT systems connect finance, marketing, manufacturing, human resources, and other parts of the firm through enterprise resource planning (ERP) systems that track orders and production output. Web-based Internet applications called extranets allow authorized external trading partners to enter protected parts of the organization’s internal systems to view relevant production schedules. Customer relationship management (CRM) systems use data mining techniques that allow sales and marketing personnel to understand historical sales data and create more personalized experiences for customers. Powerful IT-based analytical and trading tools allow financial analysts to forecast stock trends and link directly into the market to engage in electronic trading.

Occasionally, a new technology emerges that can result in major improvements in the cost-performance capabilities of the firm’s information systems (IS). Radio frequency identification (RFID) is a technology that has the potential to dramatically alter the ability of the organization to acquire data about the location and condition of any item that can be physically tagged and wirelessly scanned within certain technical limitations (Curtin, Kauffman, & Riggins, 2007). When this type of new technology comes along, it is important to have frameworks that allow managers to judge the potential business value of the technology, which can help them build the business case for related investments. Further, these frameworks can help managers develop plans for organizational change that is often needed to take full advantage of the innovation. In this research-paper, I provide an overview of RFID technology and suggest a framework to analyze the business case for adopting RFID. At the conclusion of this research-paper, the reader should have a working knowledge of some of the components that make up an RFID system, as well as an understanding of the various ways this technology can add value to today’s organization.

Background And Relevant Technical Issues

In 2005, MIT listed RFID as the 10th most innovative technology of the past 25 years ahead of hybrid cars, HDTV, the space shuttle, and nanotechnology. One reason why it is considered so innovative is that it can be used to track the location of items, monitor the surrounding environmental conditions, wirelessly communicate with strategically placed readers, and emit radio signals that can be used by other equipment to initiate changes to the object or its surroundings. Essentially, RFID has the potential to bring computer-based intelligence to any mobile item that can be tagged. For example, by tagging individual items held in a retailer’s stock room, the system can act as if there were a unique manager assigned to watch over each item in inventory. If the stockperson begins to take an item to the showroom, a tag can notify the stockperson that a different item should be taken due to its soon-to-expire expiration date. This type of micromanagement of individually tagged items can deliver efficiency benefits, make the organization more effective in its decision making, and bring strategic benefits over rivals when integrated with other systems.

Despite the recognition by MIT, RFID has actually been around for more than 25 years. An early version of this technology was used by the British during World War II to identify friendly aircraft. By placing powerful RFID tags on airplanes, these transponders could alert radar towers to their approach. As the technology improved over the next few decades, many firms began implementing antitheft systems to alert store management when an item was being shoplifted. During the 1970s, RFID technology was used to track cattle and other animals that could be tagged and then allowed to roam. In the last few years, society has seen considerable interest in this technology as large buyers have seen the potential for using RFID to track inventory through the supply chain.

Today, RFID technology is made up of three components (Information Technology Association of America [ITAA] 2004). The RFID tag is made of two items: A tiny silicon chip, perhaps a few millimeters in size or smaller, contains a limited amount of data and can receive and emit a radio signal through an attached antenna, which may be shaped in a maze-like pattern to increase the length of the antenna while keeping the size of the tag to one square inch in area or smaller. The emitted signal is read by a reader, which can be placed in many locations such as the warehouse receiving door or on a handheld scanning device. The reader is linked to other information systems, which process, store, or transfer the data to various applications.

Tag Types and Sizes

RFID tags come in a variety of sizes and shapes, which impact their cost, their read-range distances, the amount of data that they can store, and their ability to monitor more than simply location (Cooney, 2006; Finkenzeller, 2003). These all impact the usefulness of RFID for a given application. Clearly, it is important to match the technical capabilities of the tag with the business need and the physical and financial limitations of the proposed application. The cheapest tags are passive tags, which have no internal power source but, rather, draw power from the signal sent by the reader. The reader scans the surrounding area by continuously sending out a signal within a certain frequency range. When a passive tag comes within the read range of the signal, the passive tag is “awakened” and responds to the reader by transmitting an identifier code. For small, cheaper tags, this identification code may be the only data stored on the tag, but it is enough to alert the reader that it, and the item it is attached to, have passed within the read range of the reader. When read ranges are limited to a few feet, this is enough to allow the system to know that a certain tagged item has passed through the warehouse receiving door or has been shoplifted.

Active tags are larger, perhaps the size of a credit card or a cell phone, and include a battery source to power the tag, which can increase the read distance or power additional features of the tag such as an internal temperature or vibration monitor. The larger tag size also allows for more data storage capacity. In addition to storing an identifier code, these tags might log temperature readings every 5 minutes over the course of a weeklong truck haul, which can be downloaded after transport. In this way, the internal battery allows the tag to be active and engaged even when readers are not present. While more expensive and bulkier, active tags have more potential uses than passive tags, which are typically used simply to alert the system to its presence. Again, the type of tag that is right for a specific application depends on the functionality needs of the problem, size limitations, read distance requirements, and financial constraints.

Standards play an important role in maturing the technology and allowing different readers to communicate with different tags. RFID is an extension of existing barcode technology and is integrated with the EPCglobal Network. The EPCglobal Network was developed by the Auto-ID Center at MIT and is a joint venture between EAN International and the Uniform Code Council to develop, support, and promote the global adoption of the standardized Electronic Product Code (EPC) and RFID.

One question that often comes up is “why do we need RFID when we have barcodes?” Several advantages of RFID over barcodes include

- no need for line of sight scanning, which typically requires manual intervention to line up the barcode with the scanner;

- even if items could have their barcodes scanned while on a conveyor belt, they still need to be individually positioned; yet with RFID, items can be scanned while still packed deep within a pallet;

- RFID can better handle off-track items and can be used to find misplaced items in a warehouse;

- with RFID you can scan many items at once, whereas barcodes require items to be scanned one by one;

- barcodes identify the type of product, whereas the EPC code identifies a specific tag and therefore a unique item, not just item type; and

- RFID allows for dynamic data interchange with the system, while barcodes are simply identifiers.

So while barcodes will continue to be used for certain applications, RFID provides more powerful capabilities.

As I stated, RFID has been around for years, however, the adoption of the technology took a major step forward when Wal-Mart announced in 2003 that it expected suppliers to begin using RFID tags on shipped items at the pallet level by January 2005. To make it economical for both Wal-Mart and their suppliers, this type of tagging is done using small, disposable, EPCglobal-based, standardized passive tags.

Figure 90.1 Four Frequencies for RFID Applications

Figure 90.1 Four Frequencies for RFID Applications

Other major buyers soon followed Wal-Mart by requiring suppliers to implement RFID including the U.S. Department of Defense and Target (Bacheldor, 2004). With these mandates leading to widespread incorporation of passive tags on products or pallets, it is expected that the tag cost when purchased in bulk (per million) will soon drop to about $0.05 per tag. This illustrates the importance of having the backing of a large promoter of the technology, which forces adoption on a large scale. This results in a drop in the price of technology components that can be procured in bulk. Without the prospect of achieving the $0.05 per tag price, most suppliers would find adoption of this technology daunting and infeasible.

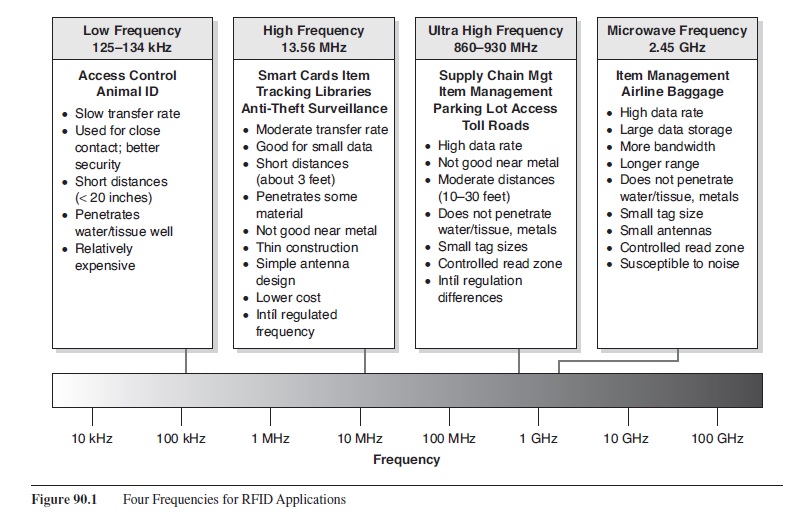

Frequencies and Read Ranges

In addition to the size and battery source, another important characteristic of RFID tags is the frequency at which they transmit their signal. Again, standards play an important role since tags and readers must be tuned to transmit and receive certain signal frequencies. Further, radio frequencies have many purposes and are closely regulated by governments, who allow specific frequency bands to be made available for certain purposes. One problem that may arise in promoting RFID usage across global supply chains is that different governments have not necessarily allocated the same frequency ranges for the same purposes. Therefore, international cooperation is critical if RFID is to be universally accepted. The frequency used not only determines the feasible distance of reading the signal, but it is also a fact of physics that certain frequencies are better at penetrating certain items such as metal, water, or skin.

There are essentially four frequencies used for different applications of RFID (see Figure 90.1). Low frequency (LF; 125-134 kHz) is used for tagging pets because it is good at passing through water and skin, but it requires a very close read range such as passing a handheld device over the pet. High frequency (HF; internationally accepted 13.56 MHz) ranges have a higher read distance and a faster data transfer. They are commonly used in retail theft-prevention applications for high-value goods, for smart cards, and for tagging books in libraries. Because they have a better read distance, HF tags can be used to find items like lost books in libraries. The tags being used in supply chain management applications as promoted by Wal-Mart and others are typically in the ultrahigh frequency (UHF; 860-930 MHz) range and are useful because of a longer read distance and the low cost of producing many tags. Also, because of a faster data transfer rate a vehicle carrying many tagged items can pass through a dock door at a reasonable speed and still achieve high read rates. Here, one sees differences in international standards: Most American applications run at 915 MHz, while Europe has developed similar applications at 868 MHz. Finally, some applications that require longer read distances and large data files may use microwave frequencies (2.45 GHz).

Depending on the size of the tag and the frequency used, the current range of reception of the reader is limited. Tags operating at 13.56 MHz have a maximum range between the tag and reader of about one meter. Some tests using the 915 MHz frequency have a range of up to 60 feet under ideal conditions. In general, tags operating at LFs (around 125 kHz) use much less power, have a limited read range, but are able to penetrate most nonmetallic substances including liquid. Tags at UHFs (860-930 MHz) use more power and are less likely to pass through certain materials.

As can be seen in Figure 90.1, depending upon the frequency used, many physical limitations can hamper the reading of the tag such as metal, water, interference from other radio signals, and so forth. It is easy for people who do not understand the technology to have fears of how their privacy may be invaded in an RFID-saturated world. However, given the limited read distances and the other factors impacting reader capabilities, it is unlikely that vans will be patrolling the streets with readers monitoring what we have inside our homes. Nevertheless, there are certain areas where security is important, and precautions by systems developers need to be considered. Having RFID tags embedded in passports, in shipping containers, in tags that contain personal medical information, or in employee badges call for particular attention to security and privacy issues. Without proper consideration of both the real and perceived potential violations of individuals’ privacy, adoption of RFID may be resisted by many individuals.

EPCglobal

As stated earlier, the cooperation of different groups and governments to create standards is critical for the seamless integration of RFID across multiple settings found in business-to-business applications, security issues related to international trade, and tracking the location history of items as they move through the supply chain (Asif & Mandviwalla, 2005). EPCglobal has played a critical role in developing these standards. EPCglobal was formed in 2003 and is a successor to the early work done on RFID standards by the MIT Auto-ID Center. Today, EPCglobal works toward global adoption and standardization of RFID using the EPC specification for identifying specific product items. Further, they seek ways to integrate the Internet with RFID to create the EPCglobal Network. The main feature of the EPCglobal Network is the EPC Information Services (EPCIS) information repository available to users of RFID technology. The EPCIS keeps track of various RFID events in the history of a given tagged item. Because the EPC identifies each unique tagged item, it is possible to track and record an historical record of where the item was at a specific point in time, the circumstances surrounding that item, and who was responsible for it at that time.

Another component of the EPCglobal Network is the Object Naming Service (ONS). The ONS is based on the domain name system (DNS), which keeps track of the virtual address of each Web site domain name. As the EPCIS historical record is maintained and updated regarding the history of an EPC-tagged item, the ONS will provide a way to allow users to log on to the Internet and use the ONS to view the historical record of the location and conditions of a item at any point in time. While there are many obstacles to implementing this type of service in practice, the concept and standards are widely agreed on, and we should expect to see applications using this type of service by the end of the decade.

The usefulness of this type of network can be seen when we consider the problems associated with events like an E. coli outbreak due to contaminated food. Using RFID, related monitoring technology, and a fully developed EPCIS, it would be possible to track the historical location record of certain food products, the environmental conditions surrounding them during transport and storage, and what other items were nearby at any point in time that could have also been contaminated. Similar systems could be used to track the location of patients in a hospital to understand the potential impact of the spread of communicable diseases. Also, an EPCIS could be used to track the history of a pharmaceutical drug to authenticate its origin and where it might have been counterfeited or tampered with at any point along the supply chain.

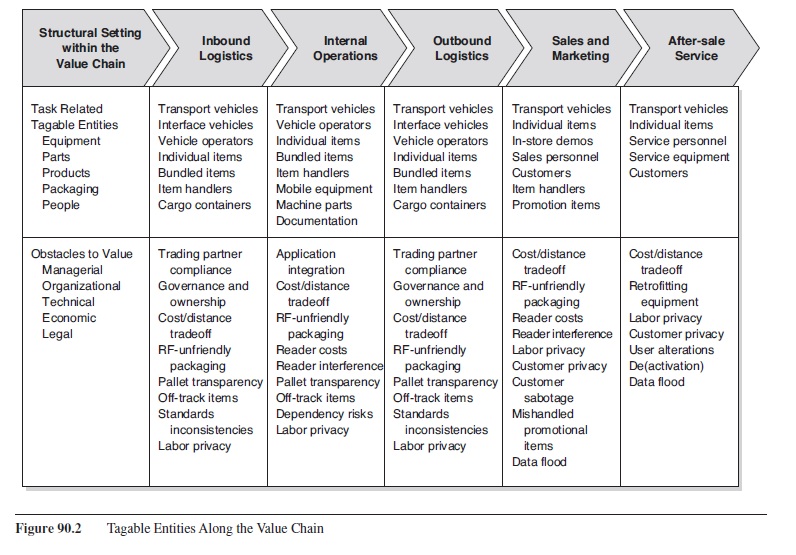

The Value Proposition Along The Value Chain

Our framework for identifying where value is generated using RFID is based on two components. First, I will examine different applications across the value chain. Specifically, RFID can be used to support activities within five different structural settings: inbound logistics, internal operations, outbound logistics, sales and marketing, and after-sale service. Each of these represents opportunities for using this technology to track the location and monitor the conditions of tagged items. Figure 90.2 provides a useful way of thinking about the different items that can be tagged including vehicles, equipment, items, and people. The figure also outlines several obstacles to achieving value from the technology. Many of these obstacles relate to managerial concerns, organizational barriers, technical limitations, economic feasibility, and legal restrictions.

Inbound Logistics

RFID can be used to monitor the location and condition of parts and finished goods while being shipped to the organization’s facilities. Having visibility into the current location and status of the shipment allows for accurate inventory management through inventory anticipation. In addition, using monitoring technology along with basic RFID technology allows the recipient to monitor the condition of items while in transit. Monitoring vibration can help predict breakage and other quality control problems. Tracking temperature, humidity, light, or air pressure during shipment can be important for certain perishable items such as food or pharmaceuticals. Just as delivery time status can impact the organization’s inventory control systems, being able to predict the condition of items when they arrive can be useful for determining appropriate routing and reorder decisions. Finally, RFID coupled with sophisticated monitoring technologies can allow the recipient of the shipment to control processes remotely during shipment. For example, when monitoring temperature in the truck, the recipient can request changes in the truck temperature or request the shipment be diverted to a closer facility rather than risk spoilage over a long truck haul over the desert.

Figure 90.2 Tagable Entities Along the Value Chain

Figure 90.2 Tagable Entities Along the Value Chain

Internal operations

Just as monitoring the location and condition of items during inbound transit directly impacts the organization’s inventory management system, monitoring the location and condition of items within the firm’s internal operations facilities impact these systems. Another area of impact is through asset management of expensive pieces of equipment, which may easily be misplaced, lost, or hoarded by employees. Hospitals, manufacturing facilities, and computer support teams can all benefit by knowing the exact location of expensive mobile equipment that needs to be at a specific location at a specific time for a specific task. This is particularly beneficial when the equipment is used by high-paid employees who otherwise may need to wait or search for the item. Finally, tracking the location of employees themselves may be beneficial to the organization for planning workflow, work assignments, and other types of employee monitoring needs. This type of monitoring must be balanced with a respect for personal privacy. RFID is just one type of monitoring technology that will make this a more delicate issue in human resource management in the coming decade.

Outbound Logistics

Just as monitoring the location and condition of items during inbound transit adds value to the firm, monitoring finished goods during outbound logistics provides an important service to customers. Being able to reroute outbound shipments as conditions change or respond to customer queries about the location and condition of items may allow the firm to gain a competitive advantage over rivals. Also, linking this tracking system with internal systems may allow the firm to carry less inventory and still be able to support a customer’s just-in-time manufacturing environment.

Marketing and Sales

In a sales floor environment, RFID systems integrated with internal operational systems can be used to reduce out-of-stock situations thereby providing the customer a better shopping experience. Similarly, there are many situations where a customer service associate needs to locate a specific item related to the customer’s visit such as a physical medical record, a book in the library, or an item stored in the backroom. By equipping the associate with handheld RFID scanners, they can quickly locate the item leading to better customer service. Smart shelves can detect when an item is not on display or has been inadvertently moved to a different location by a customer. Smart shelves can also detect when a prospective customer browses through a brochure or some other physical promotional item, which could cause a customized video to be displayed. Finally, just as tagging employees can add benefits, encouraging customers to carry RFID-enabled promotion cards can make for a highly personalized store visit. Again, personal privacy must be ensured in such situations.

After-Sales Service

Finally, tagging items that require occasional servicing may allow the maintenance personnel to quickly download repair procedures for that specific model, retrieve usage history, or help diagnose problems or retrieve suggested courses of action quickly. In the extreme case, tagged items may potentially be serviced remotely without the presence of an actual maintenance person.

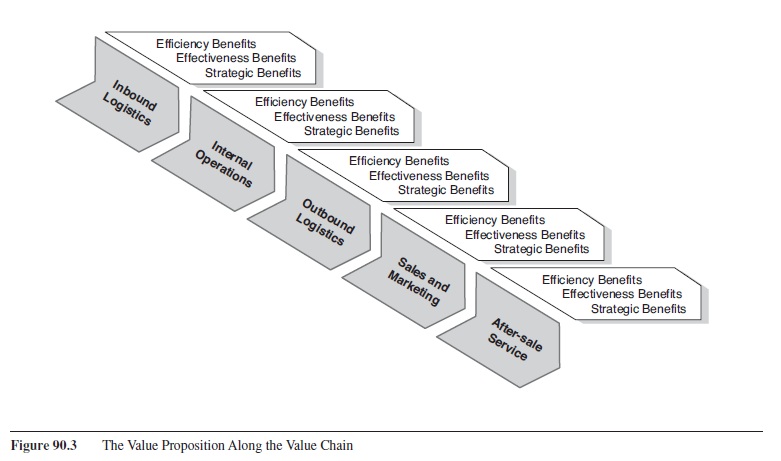

Three Types Of Investment Justification

Besides the structural setting along the value chain, there are typically three ways to think about justifying IT investments: efficiency benefits, effectiveness benefits, and strategic benefits. Improving efficiency by doing things better, faster, and cheaper has traditionally been the primary use of IT. Doing things faster with less human intervention creates a leaner, more responsive value chain and can allow the efficient organization to squeeze out inefficient competitors, which typically adds value to the end customer. IT can improve the effectiveness of decision makers by getting them the right information at the right time and in the right format. By integrating intelligent systems with RFID technology, decision makers can have real-time visibility into the location and condition of tagged items. When combined with data analytic tools, powerful decision support tools and expert systems can be implemented. Finally, when fully integrated with other systems, RFID can produce strategic benefits for firms by giving them a competitive advantage in their marketplace. This type of application typically involves working more closely with trading partners and/or locking-in users to new products and services enabled by the technology. I now look more closely at how RFID can be used to generate these three types of benefit.

Efficiency Benefits

Many processes can be done more quickly using RFID thereby creating efficiency benefits. When various items such as equipment, people, or materials are being routed through a process, their presence and/or condition can be automatically detected and logged into the system. Otherwise, they would need to be manually scanned, inspected, and logged one by one. This is a considerable time and labor savings. Further, by knowing the location and/or condition of these items, the system can predetermine optimal routing such that they can be directed to the appropriate place. Also, by using RFID systems to monitor the location and conditions of these items, the system or authorized personnel can reroute them to adjust to changing needs at various locations. Further, by monitoring the condition and environmental status of items, the system can remotely request changes in the environmental conditions around these them. This type of location and condition monitoring allows the organization to bypass employees and other intermediaries by automating the process. On the other hand, by owning the data associated with the location and/or condition of various items within the supply chain, the organization may emerge as a new intermediary that is able to collect RFID-generated data, analyze it, and offer it to interested parties. In some cases, owners of RFID-generated data may be able to understand a multiparty value chain process better than any one member of the value chain.

The real-time data gathering capabilities of RFID generates efficiency benefits by creating new forms of interaction that were previously not possible. When integrated into existing systems, a new form of automated two-way dialog can be created that can result in considerable efficiency benefits as interacting systems trigger process actions, generate real-time data updates, and monitor potential problem scenarios more efficiently than humans. In addition, this real-time data can be used to update marketing campaigns on the fly or change inventory plans on a moment’s notice. One of the most powerful ways to use IT is to use software agents to automate a series of time consuming or otherwise infeasible tasks. Software agents are intelligent applications that are able to learn from their environment and improve their performance based on data collected over time. RFID-enhanced agents that are able to monitor remotely the location and condition of mobile items have unique eyes and ears into the tagged item’s surroundings that improve their ability to learn. In this way, RFID can provide considerable efficiency benefits when integrated into intelligent agents.

Effectiveness Benefits

RFID can generate effectiveness benefits by making data and information available to decision makers in a more timely fashion. With RFID, the system is able to reflect exact current inventory levels and status conditions since systems are constantly updated to reflect the movement of items into, within, and out of the facility. By knowing the exact location and condition of items, the system can better forecast future inventory levels and conditions. By receiving real-time remote telemetry about the location and condition of various items, RFID systems can aid the effectiveness of decision makers over long distances. These systems allow managers to essentially be in multiple places at a given time by giving them eyes and ears into distant processes and locations. Further, by monitoring the location and condition of items, the system can automatically forecast future problem scenarios and can be authorized to make decisions to take into account the anticipated future location and condition of items.

RFID allows organizations to be more effective at creating a personalized service to users of the system, other internal employees, or external constituents. When the system knows the exact location and condition of various items being tracked and monitored, it is possible to provide a more personalized interface to users, present current information to decision makers, alter the work environment of employees based on who is present at the time, and provide a more unique experience to external entities. In addition to personalizing to users, RFID systems that can monitor the location and condition of mobile items, as well as the conditions of the environment surrounding them, are able to respond with intelligence to the environment itself to alter it, respond to queries, notify managers of problem areas, or make routine decisions automatically. This capability is based on predefined decision criteria as specified by management. Finally, another form of personalization occurs when decision makers use decision support systems that respond to inputs to create a unique decision output based on the decision maker’s current situation. RFID can be used to make decision support tools reflect the current location and condition of any mobile, tagged entity. These RFID-enhanced decision support tools can help users be more effective in decision making. In addition, RFID data can enable the creation of new decision support tools that were not feasible prior to RFID. In some cases, these new decision support tools can be made available to outside users, perhaps as a revenue-generating business opportunity.

Strategic Benefits

When RFID data is integrated into other systems within and outside the organization, the system can provide strategic benefits by creating a seamless flow and thus real-time availability of items across a virtual enterprise. This allows authorized users to know the location and condition of items at all times and to ensure their availability 24/7. When this capability is integrated across the enterprise and outside the enterprise to include other consortium partners, competitive advantage can be achieved relative to other organizations or consortia that do not have such seamless integration. One way this is done is to use RFID to know the current exact location and conditions of equipment, people, and other items, which allows the system to reroute these items to balance the availability of the right number of items within a globally distributed value chain. By doing so, an organization can achieve strategic benefits by extending its physical reach and locate new facilities to further locations that otherwise may not have been feasible. Virtual integration occurs when multiple parties along the value chain integrate their systems to the extent that they are able to act as if they are one entity. This type of consortium is able to achieve many of the benefits of physical integration without the difficulties of getting too large or engaging in an actual merger. RFID monitoring capabilities enhance the ability of organizations to integrate virtually by providing real-time data transfer across organizational boundaries of information associated with mobile items at any facility. By increasing the monitoring capabilities across organizational boundaries, considerable process benefits can be achieved by the consortium resulting in strategic advantage relative to competing consortia.

When RFID-generated information is valuable to users of the system, other employees, or external parties, these people typically will alter their patterns of behavior to make use of that information. When this happens, the system becomes indispensable in their job and they become locked-in to using the system. This may be a significant source of competitive advantage, particularly when the entity being locked-in is an external customer. The potential to generate benefits from RFID is enhanced when coupled with process redesign by both providers and users of the system. When this type of technology is coupled with process redesign, both parties are able to gain advantage and the implementer of RFID can achieve advantage over rivals who do not engage in such redesign. RFID systems allow organizations to gather large volumes of data that may be unique to the value chain or marketplace. When combined with sophisticated data analytic capabilities, these systems can generate unique information that may be used to create new products or services that were not previously possible. By offering this proprietary systemic competency into the marketplace, an organization may generate new revenues or enhance their competitive position within the industry.

An Integrated Framework For Building The Business Case

By combining the 5 structural settings along the value chain and the 3 ways of justifying IT investments, I can identify 15 different ways RFID can add value as shown in Figure 90.3. By thinking about the value proposition at this level of detail, a manager can ask the following questions when developing the business case for RFID:

- How can RFID be used to track the location and monitor the condition of items during inbound logistics to achieve efficiency benefits, effectiveness benefits, and strategic benefits?

Figure 90.3 The Value Proposition Along the Value Chain

Figure 90.3 The Value Proposition Along the Value Chain

- How can RFID be used to track the location and monitor the condition of items within internal operations to achieve efficiency benefits, effectiveness benefits, and strategic benefits?

- How can RFID be used to track the location and monitor the condition of items during outbound logistics to achieve efficiency benefits, effectiveness benefits, and strategic benefits?

- How can RFID be used to track the location and monitor the condition of items for marketing and sales to achieve efficiency benefits, effectiveness benefits, and strategic benefits?

- How can RFID be used to track the location and monitor the condition of items for after-sales service to achieve efficiency benefits, effectiveness benefits, and strategic benefits?

I will now use this integrative framework to examine the business case for adopting RFID in four different settings: a third-party logistics provider, a consumer goods retailer, a hospital setting, and an airline.

Case Example 1: Customer Service by a Third-Party Logistics Provider

Due to the complexities of many supply chains, intermediaries called third-party logistics providers (3PLs) often are contracted to be responsible for arranging shipment of goods from manufacturers to a retailer’s warehouse facilities. These 3PLs act as outsourcing agents by working closely with customers and their suppliers to manage a large number of trucking or rail carriers. These 3PLs add value as intermediaries in part due to the highly fragmented and independent nature of the trucking industry. In many cases, the 3PL does not actually take possession of any goods, but monitors the performance of the trucking companies to ensure their customers—for example, a large retailer—are satisfied. Using our framework, we see that 3PLs are mostly concerned with activities associated with inbound and outbound logistics.

Consider a situation where a large grocer needs to receive a shipment of fresh fruit from growers in California to warehouse facilities in the Northwest. The 3PL would be hired to be responsible to arrange shipment and guarantee a certain level of quality and freshness of the product. To do this, the 3PL would contract with a long-distance truck hauler to make multiple stops in California, haul the load of various produce items, and then unload the goods at the grocer’s warehouse facility. Clearly, there are several ways value can be added using RFID in this situation. By tagging pallets of produce at the grower’s site, the 3PL and the retailer can have visibility as to where the pallets are stored, when they are loaded onto the truck, when they are unloaded at the warehouse, and where they are stored in the warehouse. This creates significant efficiency benefits for the grocer who is able to streamline its inventory system by knowing exactly where each pallet in the shipment is and when it can be expected to arrive. Further, effectiveness benefits are realized by being able to know in real-time where the shipment is, which contributes to more effective inventory planning. Finally, to the extent to which the grocer becomes dependent upon this service, they may become locked-in to this 3PL, particularly if other competing 3PLs are not able to offer the service or are not able to make good use of the analyzed data. In an extreme case, the 3PL would be able to use this data over time to understand nuances of the supply chain that the grower, shipper, nor grocer understands.

Now consider the impact of combining RFID with temperature monitoring technology in the truck. Not only would the 3PL know the location of each pallet, but they could also know the condition of the produce by closely monitoring environmental conditions. For example, the 3PL could analyze this data to better understand temperature variations within the truck vertically and horizontally, and then instruct the trucker how to load the different types of produce on the truck (which would presumably have different tolerances for temperature variations). The 3PL could more closely monitor the performance of the trucker, the impact of opening and closing the truck doors, the impact on outside temperature variations, and the extent to which the driver is able to maintain a consistent environmental condition in the truck. The grocer would receive effectiveness benefits by being able to better route different items to the display floor. For example, due to the inevitable temperature variations in the truck, armed with this detail of historical data, the grocer could determine which packages from which pallets need to be sold first to optimize the overall freshness of the entire shipment. Ultimately, by integrating this technology seamlessly across the systems of the grower, the trucker, and the retailer, the 3PL can achieve strategic benefits by making the entire supply chain perform better relative to what the retailer could achieve through a competing 3PL.

Case Example 2: Applications By A Consumer Goods Retailer

The previous example illustrates some of the benefits a retailer can receive by integrating RFID into its inbound logistics operations as well as its internal operation by linking the warehouse to the specific stores. One of the biggest problems facing consumer goods retailers is the out-of-stock problem. For most retailing situations, it has been estimated that about 1 of 12 items is out at a given time. That means that 1 of 12 customers will either switch to a different item (meaning the customer is dissatisfied), switch to a different brand (meaning the manufacturer is dissatisfied), or not buy at all (meaning all parties are dissatisfied). In some cases, the item may be on the shelf but may have been browsed and misplaced by an earlier customer. In other situations, the item may be in the backroom, but not yet stocked, or may be misplaced in the backroom. Out-of-stocks can be a particularly large problem for manufacturers hoping to capitalize on an existing advertising campaign that may attract customers, who then cannot find the item on the shelf. RFID has been shown to lessen the out-of-stock problem for retailers that implement the technology and thereby gain better visibility into the location and condition of tagged entities (see Hardgrave, Waller, & Miller, 2005; Ton, Dessain, & Stachowiak-Joulain, 2005).

Now consider some benefits that can be obtained for a retailer’s sales and marketing efforts. The opportunities to use RFID technology combined with personalization technology for business-to-consumer marketing is both compelling and problematic (Fusaro, 2004). Retailers that offer preferred customer cards may be tempted to tag the cards so that customers can be identified when the customer enters the store. Being able to track that a customer spends 10 minutes in aisle six before moving on to spend 15 minutes in aisle four raises marketing opportunities as well as privacy concerns. Further, by tagging promotional materials, readers can note that a particular customer removed a specific product flyer from the rack and can activate follow-up marketing at a later time. Efficiency benefits can be obtained by making it easier for customers to find items in the physical store, lessen the need for sales people in the store when the system can provide customers directions, and better optimize the layout of the store to speed customer traffic into and out of the store. In-store RFID-based marketing activities of this type are sure to result in a flood of data that will require marketers to employ powerful data mining capabilities. When they do so, they will be more effective at providing a highly personalized shopping experience, make sure items are always stocked based on forecasted demand, and improve decision making regarding product ordering and new product development based on customer tastes. Finally, strategic advantage may be gained if the customer comes to rely on this highly personalized service and becomes locked-in to the service provided by the RFID-enabled retailer.

Case Example 3: Asset And Patient Management By A Health Care Provider

Hospitals are currently implementing RFID technology to keep track of expensive medical equipment to be sure the item is in the right place at the right time. This type of asset management results in considerable value for the internal operations of the health care facility. Because of the expense of the equipment and the fact that a tag will remain on the item for essentially the life of the equipment, this type of application is much better suited for more expensive, and more powerful, active tags. Because this equipment is typically used by highly paid professionals and may be needed for life and death situations, it is critical that the equipment is available when needed. Significant efficiency benefits can be realized by having the system know the location of the equipment and allowing the RFID system to interface with procedure and equipment scheduling programs. In addition to time-savings, by being able to track the location of these expensive items the hospital will need fewer pieces of equipment and thus avoid the expense of carrying excessive equipment inventory.

Hospitals are also finding useful applications for tracking patients. For many years, hospitals have been realizing efficiency benefits by attaching barcodes to the medical ID bracelets worn by patients. In addition to the benefits noted earlier of RFID over barcodes, tagging patients with RFID can be useful for tracking unauthorized movement of patients such as Alzheimer patients who may inadvertently wander out of the medical floor or perhaps even attempt to leave the hospital facility. Similar applications can be used in tracking newborn babies or other patients that require close location monitoring. For the most part, these are efficiency benefits. However, more effective planning for medical procedures can be done when the system tracks the movement of patients throughout the facility.

Just as efficiency benefits can be realized by tagging patients, so too by tagging employees. For example, physicians move in and out of many rooms during a typical day at the hospital. In many instances, the physician is required to log into the system with each new patient room visit. By tagging the physician’s name badge and having the system automatically log the physician in when entering the room, considerable efficiency benefits can be realized.

Health care facilities and workers also face the regrettable situation of facing lawsuits due to mismanaged drug administration. Consider the benefits that can be realized if the RFID-enabled system sensed that an individually tagged drug dosage, currently residing in a health care professionals coat pocket, entered a room that housed a patient for which that dosage was not intended. The system could alert the professionals of various drug interactions or other detrimental effects of mistaken drug management.

Finally, a related application of RFID is being pursued by pharmaceutical companies that seek to tag and track packaged drugs to avoid drug counterfeiting that can cost these companies millions of dollars. Other resulting benefits of tagging pharmaceuticals include providing blind patients with devices that sense a nearby pill bottle and audibly speak to the patient about the contents of the container.

Case Example 4: Luggage and Customer Tracking by an Airline

Another business sector that can readily benefit from RFID tracking is the airline industry. When airlines consider customers as valuable entities that enter and eventually leave the airline system, we can see that all five structural settings of the value chain can be impacted by RFID. For example, several airlines have begun testing the potential for tracking customer baggage by including an RFID tag on each checked bag. Delta Airlines believes there are significant efficiency benefits to be realized since the airline currently spends tens of millions of dollars locating 800,000 misdirected bags each year. Overall, Delta handles 70 million pieces of luggage each year (Brewin, 2004). Here, RFID can have efficiency impacts on the baggage check-in process (inbound logistics), movement of bags and customers throughout the airline system (internal operations), the baggage claim process (outbound logistics), and home delivery of misplaced bags (after-sales service). Airlines that are able to use this technology effectively can achieve customer service benefits that may lock-in customers to that airline thereby creating strategic benefits.

Most airlines have also moved to e-tickets or ticketless processes. However, imagine the value of having flyers carry RFID-tagged tickets. Airlines can know the location of customers as they move through security checkpoints or through the airport between connecting flights. This would result in significant efficiency benefits as well as a much more personalized and, therefore, effective customer experience. Airports that compete for hub traffic may be able to gain competitive advantage over airports in rival cities as airlines choose to route their traffic through RFID-equipped smart airports.

Improving The Usefulness Of RFID

In this research-paper, I have provided an overview of RFID, the components of an RFID system, and the relevant technical factors that drive construction of an RFID system for a particular application. Further, I have highlighted how RFID can deliver three types of value within five structural settings along the value chain and have provided four examples of how RFID is used in commercial settings today. It should be clear that this technology has considerable potential for impacting the organization at various points across, and beyond, the enterprise. However, realizing its full potential will be difficult and require considerable investments. In concluding this research-paper, I offer four areas where management needs to be diligent if value is to be realized to its fullest extent (see also Clarke, Tazelaar, Twede, & Boyer, 2006).

First, research on related technologies such as electronic data interchange (EDI) has shown that investment in the technology coupled with business process redesign is the best way to maximize investment dollars. Specifically, investment in new technologies is an opportunity to examine how processes should be redesigned to take advantage of the technology capabilities. New technologies may automate tasks resulting in efficiency benefits, empowering decision makers with decision support tools for effectiveness benefits, and create closer electronic trading partner relationships with alliance partners to generate strategic benefits. However, all are best realized when processes are redesigned to take advantage of the new technology.

In particular, strategic benefits are best realized when new technology results in closer trading partner cooperation. Also, because RFID is often used as a way to connect trading partners, gaining efficiency and effectiveness benefits often requires certain actions on the part of the trading partner. For example, many benefits occur when one’s trading partners integrate the RFID system back into their existing internal systems. This requires considerable trust and cooperation within the trading partner alliance.

The third recommendation is that organizations seek to integrate RFID systems into their existing systems. To comply with trading partner mandates for adoption, many organizations are adopting RFID as minimal “slap and ship” systems. However, firms that adopt this technology at such a rudimentary level leave many potential benefits on the table and will likely have trouble justifying such investments on simple return on investment calculations.

Finally, RFID will result in a massive new influx of data into the organization as readers monitor the movement of many items and multiple physical locations on a continuous basis. To make full use of this data, new data analysis tools will need to be employed to mine that data to understand fully the implications of how processes need to be changed, how customers can better be served, and how the data can be used to create new information-based products for customers.

Firms that follow these guidelines and seek to uncover different types of value at multiple points along the value chain are the ones that will most benefit from this new technology. These firms will be the ones that will lead the value creation effort in the emerging new world of ubiquitous computing.

References:

- ALX Technologies. (2006). RFID Update—The RFID Industry Daily. Retrieved September 2, 2007, from http://www.rf idupdate.com/

- Asif, F., & Mandviwalla, M. (2005). Integrating the supply chain with RFID: A technical and business analysis. Communications of the Association for Information Systems, 15(24), 393-426.

- Bacheldor, B. (2004). Target pushes RFID adoption. Information-Week, 978, 18.

- Brewin, B. (2004, April 1). Delta begins second RFID bag tag test. Computerworld. Retrieved September 2, 2007, from http:// www.computerworld.com/newsletter/0,4902,91826,00.html

- Cooney, E. M. (2006). RFID + : The complete review of radio frequency identification. Clifton Park, NY: Thomson Delmar Learning.

- Clarke, R. H., Tazelaar, J., Twede, D., & Boyer, K. K. (2006). Four steps to making RFID work for you. Harvard Business Review, 1-4.

- Curtin, J., Kauffman, R. J., & Riggins, F. J. (2007). Making the “MOST” out of RFID technology: A research agenda for the study of the adoption, usage and impact of RFID. Information Technology and Management, 8(2), 87-110.

- (n.d.). EPCglobal. Retrieved September 2, 2007, from http://www.epcglobalinc.org/home

- Finkenzeller, K. (2003). RFID handbook: Fundamentals and applications in contactless smart cards and identification (2nd ed.). Hoboken, NJ: John Wiley and Sons.

- Fusaro, R. A. (2004). None of our business? Harvard Business Review, 82(12), 33-44.

- Hardgrave, B. C., Waller, M., & Miller, R. (2005, November).

- Does RFID reduce out of stocks? A preliminary analysis. Report from the Information Technology Research Institute, Sam M. Walton College of Business, University of Arkansas. Retrieved September 2, 2007, from http://itri.uark.edu/re search/display.asp?article=ITRI-WP058-1105

- Information Technology Association of America. (2004, June). Radio frequency identification: RFID . . . coming of age. Arlington, VA: Author. Retrieved September 2, 2007, from www.itaa.org/rfid/docs/rfid.pdf

- RFID Journal. (2007). RFID Journal—RFID (Radio Frequency Identification) Technology News & Features. Retrieved September 2, 2007, from http://www.rfidjournal.com/

- RFID News. (2007, August 31). RFID News: Technology, Tags,EPC, Wal-Mart, Readers, and Applications. Retrieved September 2, 2007, from http://www.rfidnews.org/. RFID

- Research Center. (2007). RFID Research Center [Home page]. Retrieved September 2, 2007, from http://itri.uark .edu/rfid/

- Strategic RFID Solutions. (2007). Strategic RFID Solutions home page. Retrieved September 2, 2007, from http://www.strate gicrfidsolutions.com/

- Ton, Z., Dessain, V., & Stachowiak-Joulain, M. (2007). RFID at the METRO Group. (Case, rev. ed. No. 9-606-053). Boston:Harvard Business School Publishing.

See also:

Free research papers are not written to satisfy your specific instructions. You can use our professional writing services to order a custom research paper on any topic and get your high quality paper at affordable price.